Specialised Grouting Services

Providing quality grouting and expert advice

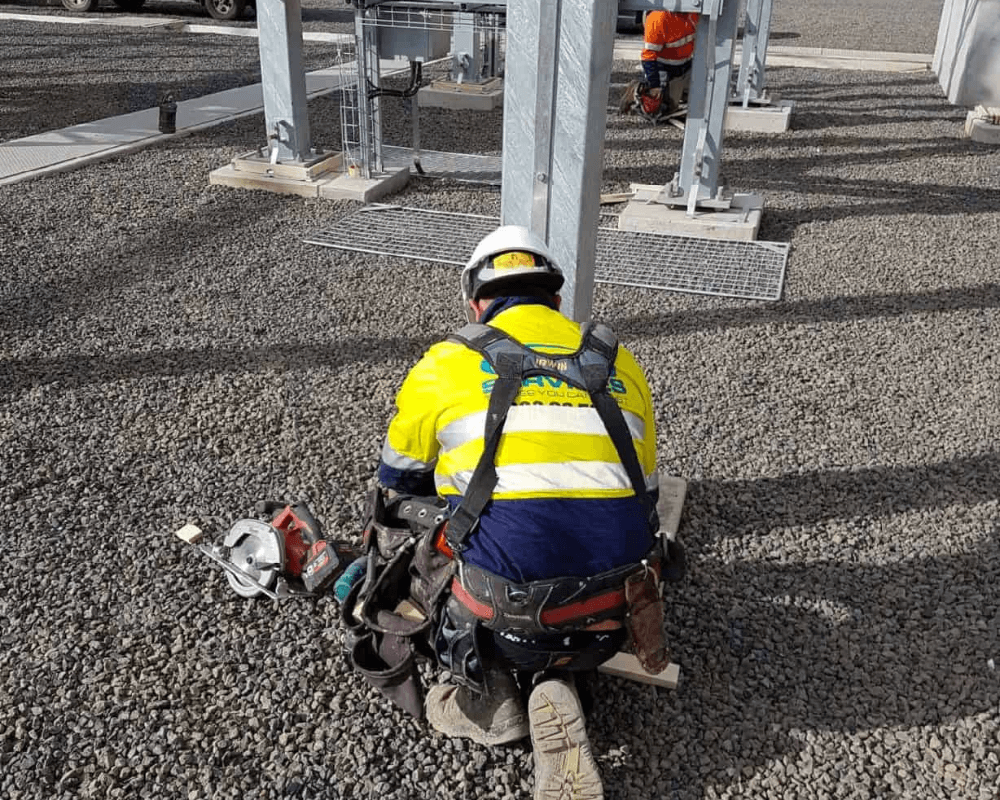

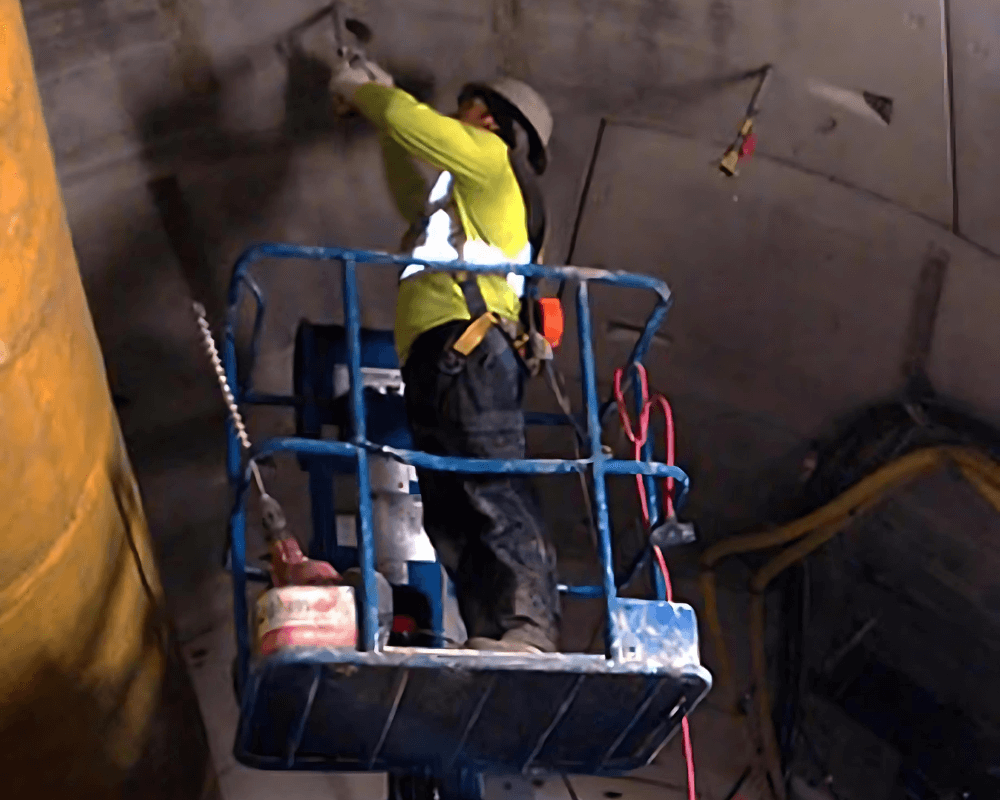

AWS Services proudly offers comprehensive grouting solutions to meet a wide range of structural needs. With a proven track record of successful projects, our team of qualified and experienced technicians utilise advanced techniques, high-quality materials, and specialised equipment to deliver precise, durable, and reliable results. Backed by years of hands-on experience, AWS has the knowledge and capability to provide the right grouting solution for your project — carried out to the highest professional standards.

Get Your Free, No-Obligation Waterproofing Quote Today!

Expertises and Techniques

Sectors We Serve

Our company is able to tap into a wealth of experience, and using proven, best practice methods offer a wide range of technical techniques and expert services to our clients.

Precision Grouting

Tunnel Grouting

Wind Turbine Grouting

Mine Infill/Stablisation

Rock Anchor Grouting

Seawall/Dam Grouting

Road Void Grouting

Jet Grouting

Material: Epoxy Grouting

Discover enhanced durability with our epoxy grout applications. Our experienced team have the capability to provide precise and controlled epoxy grouting for your projects, providing lasting structural integrity and reliability.

Benefits:

- High strength

- Excellent adhesion

- High density

Uses:

- High strength bases for Turbines and Machines

- Excellent adhesion with Epoxy grouts

- Special grouts for machines base vibrations

- Very high density suitable for radioactive screening

- Superb Grout for tiling applications

Material: Cementitious Grouting

Discover how AWS Services excels in cement grouting solutions. Our experienced team delivers reliable cement grouting services tailored to meet your specific needs, ensuring structural integrity and longevity.

Benefits:

- High strength

- Low cost

- Readily available

Uses:

- General filling

- Consolidation of granular material including gravel

We Inspect, Diagnose, and Implement Cost-Effective Grouting Solutions!

AWS Services excel at dealing with all types of repairs. When a client gets in touch with us, we send over a team of experts who inspect the structure, diagnose the problem, and implement an effective strategy that is not only budget-friendly, but also ideal for preserving your building.

Why choose AWS for your grouting needs?

Given the duration we have been in the industry, Our team has encountered almost everything that there is to be found, our wide knowledge base puts us miles ahead of our competition. Regardless of the situation, we will have a solution for your needs. Our machinery and capability are of the highest standards in the industry and we pride ourselves on completing projects on time and hassle free to our clients.

For a trusted partnership that will not let you down when you need it most, call AWS today to experience the difference. We stand by our workmanship with warranties you can count on.

Related FAQs about Grouting Services

What is industrial grouting, and when is it required?

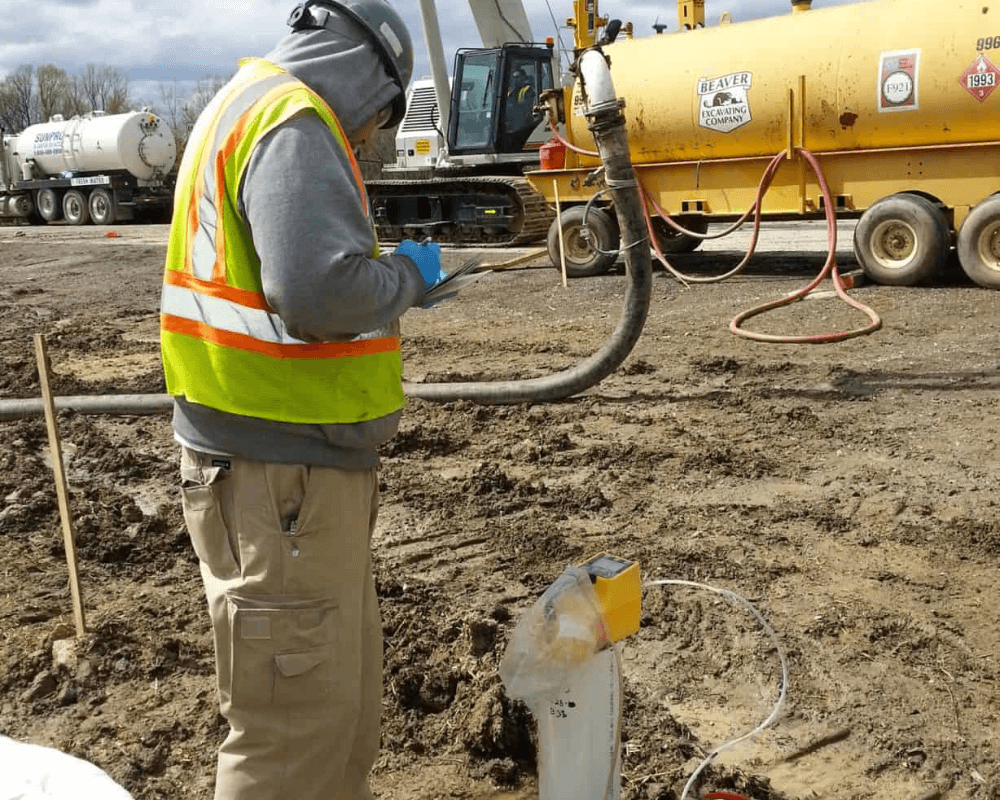

Industrial grouting is the process of injecting or placing a high-performance grout material beneath structural elements, machinery bases, or in voids and joints, to achieve load transfer, alignment, stabilisation or sealing. It is required where precision bearing surfaces or void fills are needed — for example under equipment baseplates, between slab and steel frames, or in foundation stabilisation works.

What’s the difference between epoxy and cementitious grouting?

Cementitious grouting uses a cement-based binder (often with sand and additives) and is suited to static loads and larger volume fills; whereas epoxy grouting uses a two-part resin and hardener system and is designed for high-precision, high-load, or dynamic environments. Epoxy offers superior bond strength, chemical resistance, and vibration tolerance, while cementitious grouts often cost less and perform well in high-temperature or large static-fill situations.

How do you determine which grouting method is right for my project?

The right method is selected by assessing the operating conditions of the structure or equipment: load magnitude, whether there is dynamic or impact loading, exposure to chemicals or moisture, temperature extremes, and required turnaround time for the installation. If the machinery base experiences vibration or rapid cycling, epoxy may be the better option; if the environment is heat-intensive or the fill volume is large and static, a cementitious grout may be preferred.

Which industries and structures benefit most from professional grouting?

Industries such as manufacturing (heavy machinery, press works), mining, power generation, infrastructure (bridges, tunnels), commercial flooring and large structural installations all benefit from professional grouting. Structures that demand precision alignment, high load transfer, void correction under slabs, or stabilisation of foundations are ideal candidates for industrial grouting services.

What makes precision grouting critical for heavy machinery installations?

Precision grouting ensures full bearing contact between baseplate and foundation, minimises differential settlement, controls vibration transmission, maintains alignment tolerances, and protects against premature wear or mis-alignment of high-performance machinery. Without it, the risk of maintenance, downtime, performance loss, and structural damage increases significantly.

Can grouting be used for infrastructure repair or void stabilisation?

Yes. Grouting is commonly used to fill voids beneath slabs, pavements, or structural elements, to underpin foundations, correct settlement, stabilise soil or rock beneath

infrastructure, and tie new works into existing concrete. Structural grouting is an established technique in infrastructure remediation and is critical in ensuring long-term stability.

How long does a typical grouting project take from assessment to completion?

The duration varies widely depending on the scope: a small machine base pour might take a few hours to one day from inspection through placement; a major remediation or large foundation void-fill might take several days to weeks including assessment, design, mobilisation, pouring and curing. Planning and diagnostics are essential to minimise disruption and ensure quality.

Why choose AWS Services for industrial grouting in Australia?

AWS Services brings deep experience in heavy-duty grouting and structural remediation, backed by qualified technicians, proven methods, and premium materials. From initial assessment through to finish and hand-over, AWS delivers solutions tailored to the performance demands of your asset, ensuring alignment, durability and operational continuity.

Get Your Free, No-Obligation Waterproofing Quote Today!