Concrete Repair Melbourne

Over 25 years of experience across Melbourne and Victoria

At AWS we have the knowledge and the skills to restore and protect your concrete assets, from car parks to bridges and commercial buildings. With over 25 years of experience, AWS delivers solutions that add strength and longevity back into your structures, ensuring you receive a durable and long-lasting finish from a company with a proven reputation.

Get Your Free, No-Obligation Waterproofing Quote Today!

Comprehensive Concrete Repair Services in Melbourne

At AWS we offer a complete range of concrete repair and restoration services, covering all regional and city areas. Our qualified team of technicians can address every kind of concrete issue, ensuring each project receives the correct solution. Free quotes and professional advice are available to help you make an informed decision about the most effective solution. Our Concrete Repair Services Include:

- Concrete Cancer/Spalling Repairs

- Concrete Crack Injection

- Concrete/Masonry Facade Restoration

- Concrete Expansion Joint Repairs

- Concrete Resurfacing & Coating

- Concrete Road & Bridge Construction Works

- Commercial Slab Jacking/Underpinning

- Waterproofing of ALL Concrete Structures

We Inspect, Diagnose, and Implement Cost-Effective Concrete Repair Solutions!

AWS Services excel at dealing with all types of repairs. When a client gets in touch with us, we send over a team of experts who inspect the structure, diagnose the problem, and implement an effective strategy that is not only budget-friendly, but also ideal for preserving your building.

We are 'NO.1' Concrete Cancer Specialists

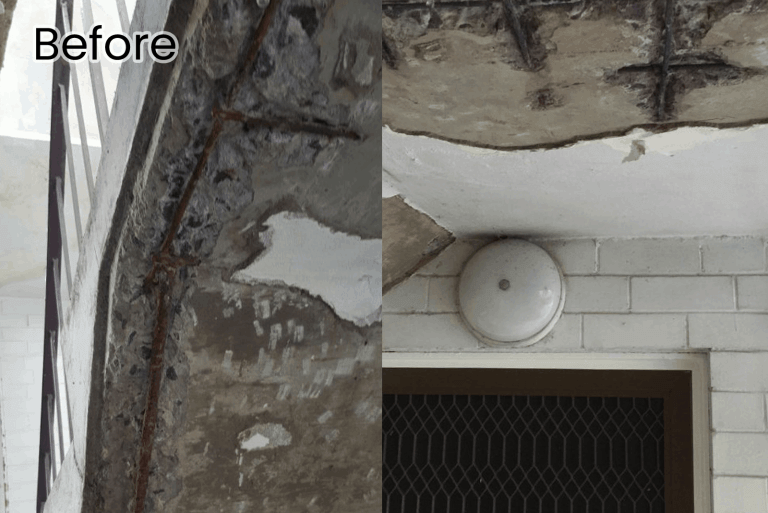

Concrete Spalling Remediation

When fixing concrete cancer or cracks due to movement, you must take into account why the problem has occurred and the fact that the problem must be fixed prior to the concrete being fixed. We specialise in the repair of concrete by identifying the cause first, solving that and then fixing the concrete structure.

Our Concrete Cancer Repair

Concrete Cancer is caused when the steel reinforcing within a concrete slab begins to rust. As steel rusts it can expand up to 7 times its original size causing the surrounding concrete to be displaced and flaky. As the steel pushes the concrete away, more water gets to the steel expediting the process.

AWS can repair the steel within the concrete and then repair the concrete itself. Each situation is unique and requires different solutions. Once we are on site we will advise you on which system you should undertake in order to rectify your situation properly.

Where the issue has originated in the slab on the roof of the building structure, in most cases it is likely that waterproofing will need to be undertaken. Once the rusted reinforcing has been treated, application of a waterproofing membrane will help prevent access of moisture to the slab and prolong the life of the steel and therefore the structure itself.

Heritage Pool

Strata Building

Bridge Deck

Concrete Culvert

Our Concrete Repair Methods

· Surface Preparation – Removal of damaged concrete and cleaning of reinforcement Steel to ensure a strong bond.

· Crack Injection – Sealing and stabilising cracks using epoxy or polyurethane resins for structural and waterproof integrity.

· Spalling Repairs – Rebuilding areas affected by concrete cancer using compatible repair mortars and corrosion inhibitors.

· Resurfacing & Coating – Restoring worn or damaged concrete surfaces for an improved, durable finish.

· Protective Treatments – Applying sealers or membranes to prevent moisture and chemical ingress.

Our Concrete Repair Projects

Road Barrier Repair

Concrete Coating

Concrete Waterproofing

Concrete Facade

Concrete Joint Repairs

Concrete Injection

We Inspect, Diagnose, and Implement Cost-Effective Concrete Repair Solutions!

AWS Services excel at dealing with all types of repairs. When a client gets in touch with us, we send over a team of experts who inspect the structure, diagnose the problem, and implement an effective strategy that is not only budget-friendly, but also ideal for preserving your building.

Related FAQs about Concrete Repairs

What Is concrete spalling (concrete cancer)?

Concrete cancer is characterised by the deterioration or detachment of the concrete surface, often indicated by cracks, crumbling or flaking, as well as the presence of rust stains or bubbles on the concrete or cement render, and may also cause leaks in concrete roofs and walls. Concrete cancer, on the other hand, refers to the progression and exacerbation of concrete spalling. However, these are generally accepted to be the same and most commonly is referred to as either to describe the deterioration of concrete.

What are the causes of concrete spalling?

Concrete Spalling, commonly referred to as Concrete Cancer, is a severe deterioration of steel reinforcement beams within a concrete slab. This process poses significant risks to the structural integrity of both the building and its flooring. AWS Services offers complimentary inspections of concrete slabs to detect any signs of Concrete Spalling. This assessment is particularly crucial before installing new floor toppings, especially following the removal of Magnesite Flooring. Beyond aesthetics, Concrete Spalling is more than a mere cosmetic concern. In public or worker-accessible areas, it can pose hazards from falling debris or tripping risks. Neglected, Concrete Spalling can worsen, potentially destabilising the structure. Proper maintenance is essential, with legislation placing an obligation on owners to ensure safe structures. Commercially, leaving a structure to deteriorate diminishes its value and increases maintenance costs due to widespread corrosion and Concrete Spalling. Unattractive and potentially hazardous environments, such as deteriorated car parks, deter customers.

What are the signs of concrete cancer?

Concrete cancer exhibits several unmistakable signs, with the most evident being spalling. However, even before visible cracks emerge, there are early warning signals such as deteriorating concrete, internal wall leaks, wall expansion, bubbling concrete render, and the presence of rust stains. These indicators offer insights into the underlying issues within your walls.

Does building insurance cover concrete cancer in Melbourne Victoria?

What materials are used to fix concrete concrete cancer?

When drafting a scope of works, it is important to consider the specific requirements of each product manufacturers specifications for repair materials. Each manufacturer will have slightly different specifications. These can generally be summarised by the following:

- Mix ratios.

- Cover depth.

- Minimum/maximum thickness per layer. Most HBM (High build mortar) can be build up in layers to reach the finish level.

- Are primers required for adhesion?

- What is the approved reinforcement coating (Rust inhibitor)

- Are waterproof properties required – there are HBM products that have waterproof properties.

- Specific requirements. In some cases, there are specifications for products, VicRoads will only accept certain products or “approved equivalents”.

What are the top tips to consider when scoping repairs?

In the absence of supplied specification, there are things that you will need to take into consideration while preparing a scope of works and methodology for the repair.

These considerations include:

- Extent of the concrete spalling

- Depth of the spalling

- Deterioration of the reinforcement

- Access to the area requiring repairs.

- The scope of work will generally remain the same for all access types, however, this will affect the size of your crew on site and your access plant (EWP) or scaffolding or confined space. Note: Never scope concrete cancer repairs to be carried out off a ladder.

- Location of the concrete spalling

- Proximity to the ocean, if the suburb is near the beachfront.

- Is the spalling subgrade? – below ground or retaining wall?

- Is there any plumbing around the spalling?

- Where concrete spalling has occurred on the soffit of a suspended slab, are there floor wastes on the FFL (Finish Floor Level)

- Where spalling has occurred on the perimeter edge of a concrete slab, you should take note of whether there is a drip edge. Drip edges can either be cast in or installed post construction – common where tiling is the applied finish or on Concrete roof slabs where a roof sheet overhangs the slab.

- Site requirements.

- Government/Local Council

- Residential

- Industrial

- Commercial

- Construction

- Each of these sites will have its own requirements as far as safety, noise, dust control, work durations and minimum crew sizes. This will affect the methodology as there may be requirements for spotters where EWPs are in use, or working at heights in general. There may be restrictions on working times.

- Falling Concrete.

- Where there is a body of water or river, it is important to consider, especially on government/local council sites. Concrete falling from the repair cannot enter the water. You will need to consider methods to collect the concrete as well as dust control.

You will also need to take into consideration an anti-rust coating for the reinforcement before applying a repair mortar to the area that requires repair.

What is the checklist to remember when performing concrete cancer repairs?

The below is not an exhaustive list of things to remember, each site will have its own set of circumstances, however, this is a good starting point.

- Site Type:

- Government/Local Council

- Residential

- Industrial

- Commercial

- Construction

- Photos of the repair area clearly identifying the concrete damage and surroundings.

- Access to the repair area.

- Where access exceeds 4m you will either need to allow for an EWP or a scaffolding by an authorised person.

- Site circumstances, be sure to consider probable causes for the spalling.

- Check for plumbing.

- Check for FFL drainage (where there are tiles, check for tiles that have peeked or are drummy, which would indicate that water is getting under them, and the concrete is remaining wet)

- Check for planter boxes on the top of the concrete spalling

- Check for drip edges on the edge of the concrete.

- Measure the general area of the spalling so that you are able to make an estimate on the required materials for the repair.

- Consider the nature of the site. What kind of corrosive elements is the concrete subjected to? In some cases, more commonly in industrial sites, the concrete is subjected to highly corrosive materials and liquids.

- Take into consideration any site conditions that may cause difficulties with the repairs.

- Access issues like water under bridges

- Car parks will need isolated work areas

- Falling concrete protection

- Cordoned off work areas where the public might be affected.

- Overhead power lines if you are working on a scaffold or EWP.

- Permits for footpaths if required – these will need to be factored into your estimate.